In every domestic, industrial and commercial

establishment there is need of electricity and for measuring power consumption

energy meters are installed in all establishments.

For domestic connections usually direct meters are

used means power supply wires are directly connected at input and output is

withdrawn from its output and for large and commercial establishments CT

operated energy meters are used as direct meters are not feasible to install as

size of these energy meters will be very high. It is usually recommended to

install CT operated meters if load requirements from energy meters are more

than 15 KW.

CT operated meter is most preferable meters in all

establishments as they are easy to install and operation is very simple.

In this article we study about installation of energy

meters both Houses and as well as commercial and industrial establishments:-

In Domestic connections both single phase and three

phase energy meters are used:-

For single phase meters wiring is quite simple there

are 4 terminals at the meter, 2 No’s for input power supply and 2 no’s for

output power supply. Wiring diagram for installation of single phase energy

meter is as below:-

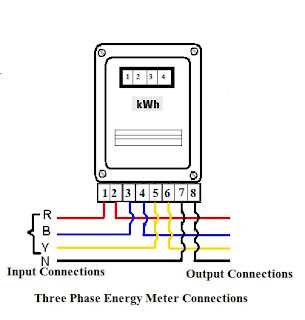

For Three phase Energy meters:-

For installation of these meters there are 12 No.s

terminals 6 no.s for three phase power supply at Input and 6 no’s for output

power supply .

Connection for three phase energy meters are as

below:-

CT operated energy meter installation:-

For installation of CT operated energy meters 1st

you have to install CT’s at Input cable as per your load requirements. These

energy meters can be used for measurement of consumption for any load only CT’s

are required to be selected according to load. As power consumption indicated

in energy meter is multiplied by CT ratio of energy meter.

Various Connection diagram for energy meter

(i)

3 CT, 4 wire

connections

(ii)

3 Wire, 2 CT

connections

are as below:-

In these meters there are no output terminals as these

energy meters are serving the purpose of measuring the energy consumed in

circuit. CT output wires are connected at terminals provided for connections of

CT’s and apart from CT connections there are three terminals provided for

connections for three phase voltages.

Now after doing all connections CT ratio needed to be

entered into energy meter so that energy meter reads the correct power

consumption consumed in system. If you don’t enter correct CT ratio then you

may not get correct results.

Now after doing all connections and programming in

energy meter , energy meter starts working when power supply get charged.

There are energy meters also available where you need

not enter CT ratio in energy meters instead energy consumption displayed on

energy meter needed to multiplied by CT ratio to arrive at actual consumption.

There are many parameters which can be monitored through

these energy meters. There are energy meters available in market which works on

2 Quadrant and 4 quadrant. 4 quadrant meters works on both lead and lag power

factors i.e. energy meter reading keeps on increasing in case of lead power

factor also. But on the other hand in 2 quadrant energy meters , energy meter

works on lag power factor only i.e. these energy meters don’t work in lead

power factor.