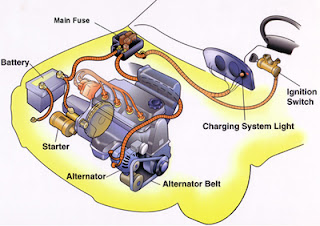

Alternator in Cars

Alternators are used in cars to generate current for running of cars. We

quite often get confused that why alternator is required when there is battery

available in cars.

Battery in cars is only used for starting the cars, but for lights

operation and functioning of other parts current is required now from where

that power will come???

For fulfilling the above purpose alternator is required, alternator has

following functions in cars:-

(i)

Running of lights, heater, Air conditioners and operation of other

electrical accessories

(ii)

Recharging of battery as it get discharged during starting.

Now how this alternator works in cars and who provides mechanical power

to alternator so that power output can be generated at alternator output??

When you switched off your car engine than radio of car will work on car

battery. For engines running following are required:-

(i)

Air

(ii)

Fuel

(iii)

Spark

Last part is supplied by alternator because spark is generated through

electricity, although battery is

available for supplying the spark but not for keep running the car. Battery

electricity is sufficient for keep running the vehicle for few KMs but vehicle required much more than that , so to serve the purpose

alternator will comes into picture.

Alternator in vehicle has output of 13.5 - 14.8 volts.

In past generators were used in cars, these generators are very

inefficient in comparison to alternators, also at that time charging of battery

and keeping accessories lighting up was different from present scenario. There

are following components of alternators:-

(i)

Stator

(ii)

Rotor

(iii)

Voltage regulator you can also say automatic voltage regulator

(iv)

Direct current circuitry consisting of diodes

Now with rotation of rotor electricity get generated and output is used

for charging batteries and keeping the auxiliaries ON.

DC circuitry is used to convert the alternating current generated by

alternator to DC. Voltage regulator is used to keeping the voltage generated by

alternator within limits. Feedback is

received by voltage regulator and accordingly output gets controlled. Now day’s voltage regulators are integral

part of alternators. But in past voltage regulators were big boxes and they

were kept in hood and wired into the system. Voltage regulator functions are as

below:-

(a) Cut off the power to battery when

battery get fully charged i.e. when battery voltage reached certain level

around 14.0-14.5 volts

(b) To keep voltage level within limits as

per requirement of auxiliaries.

How to get noticed that

Alternator is faulty??

It can be easily detected as you will observe reduced illumination from

head lights , sometimes reduced illumination may not get detected while driving

as during that time battery will provide necessary electricity . But as battery

power get used for illumination of headlights now when you tried again to restart

the vehicle then vehicle doesn’t start as battery get drained up.

Starting current of a car:-

When you tried to start a car your battery should be strong enough to provide crank to engines so that car get started easily. You may often see that very heavy leads are connected at battery terminals as starting current is very heavy for starting the car. By Ohms law we know that Voltage = Current X Resistance and now Voltage of battery is 12 V and starter motor resistance is approximately 0.12 Ohm so